-

General Tyres

-

OTR Tyres

-

Batteries

Need a new battery?Our stores stock a wide range of batteries for all vehicle types. - Stores

-

Corporate

Commitment to qualityBridgestone Tyres Papua New Guinea is the tyre industry market leader, renowned for producing quality products and being at the forefront of technology, innovation and continuous improvement.

Tyres for all

vehicle types

Truck & bus tyres

- General Tyres

- / Truck & Bus

The best tyres for your business.

If you’re in the transport business, you want to keep your profits up – without compromising on safety or performance. Which is why you should fit our Bridgestone truck and bus tyres.

Our investment in tyre research and development has helped us build a range of innovative, hi-tech and cost-effective solutions for the many challenges faced by the road transport industry.

Bridgestone L355

Bridgestone M748

Bridgestone V-Steel Jamal

Book Now

Fleet Manager Request

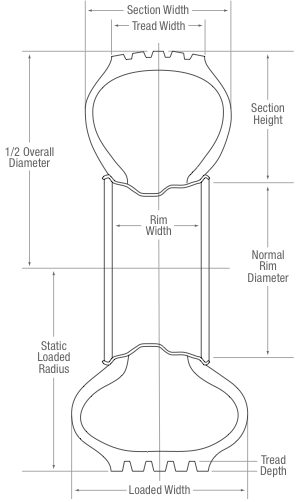

Aspect Ratio

Section Height

--------------------- x 100 %

Section Width

Overall Diameter (OD)

The measurement of the distance of an unladen tyre from tread surface to tread surface on opposite sides of the tyre.

Overall Width (OW)

Measurement of the cross section of an unladen tyre, including ribs and protrusions. Usually the same as section width on radial tyres.

Section Width

Measurement of the cross section of an unladen tyre across the casing only – not including ribs or protrusions.

Tread Width

Distance across the tread face of an unladen tyre.

Tread Depth

Distance from tread surface to major groove base at a designated measuring point.

Section Height

Distance from the bead seat to the tread surface of an unladen tyre.

Rim Width (RW)

Distance between the rim flanges.

Nominal Rim Diameter

Diameter of the rim from bead seat to bead seat in inches.

Static Loaded Radius

Distance from the centre of the axle to the ground of a loaded tyre under maximum dual load and inflation pressure.

Loaded Width

The maximum section width of a loaded tyre under maximum dual load and inflation pressure.

Minimum Dual Spacing

The minimum allowable distance between the wheel centre lines in a dual arrangement.

Revolutions Per Kilometre (RPK)

The number of tyre revolutions in one kilometre, measured at: 100km/h, maximum dual load and inflation pressure.

NOTE: All dimensions measured following a 24-hour inflation period.

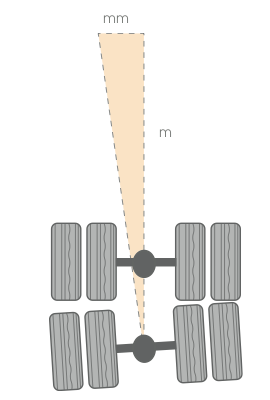

Dual tyre assemblies are commonly used on drive and trailer axles, however, they do require attention if tyre life is to be maximised.

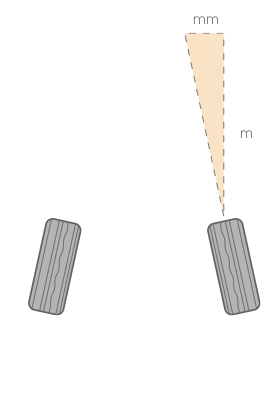

Diameter Variations

Dual assemblies with significantly different diameters will return less than optimum wear results because:

- The tyre with the larger diameter will carry more of the load, causing rapid wear.

- The tyre with the smaller diameter will be subjected to very high levels of slip, creating rapid and irregular wear.

Pressure Differentials

When tyres in a dual assembly are inflated to different pressures they will return less than optimum wear results because:

- The tyre with the higher inflation pressure will have a higher contact pressure with the road, carrying more of the load causing rapid wear.

- The tyre with the lower inflation pressure will have a lower contact pressure with the road resulting in rapid and irregular wear.

Recommendations

Bridgestone recommends that the same brand, pattern, size, load index and speed symbol be used when matching duals. The following upper matching limits for dual tyres should also be observed:

| Tyre width | Less than 9.00" | More than 9.00" |

|---|---|---|

| Overall diameter difference | 6mm | 8mm |

| Tread depth difference | 3mm | 4mm |

| Inflation pressure difference | 5% | |

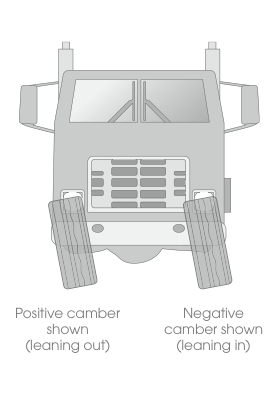

A vehicle’s wheel alignment can have a dramatic effect on how evenly and quickly the tyres wear. The following diagrams illustrate the key alignment parameters.

Steel Axle Toe (mm/m)

Rear Drive Axle Square (mm/m)

Steel Axle Camber

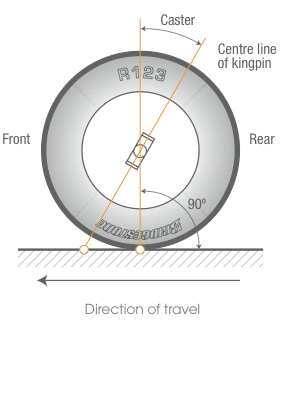

Positive Caster Angle

Typical Alignment Settings*

| Parameter | Typical Range | Explanation |

|---|---|---|

| Steer axle toe (total) | 0mm/m to +1.5 mm/m | Toe out can cause instability, so is unacceptable. Must be measured to thrust centreline. |

| Steer axle camber | L 0° to -0.6° R +0.6° to +1.5° | Slight RH positive camber can help to overcome road camber effect. It must be on the RH side because the LH side carries higher load and operates on greater road camber. It will suffer inner shoulder wear if negative camber is excessive. |

| Steer axle caster | L +3° to +4.5° R 0.5° to 0.75° less than left | Slightly more caster on the left induces a slight RH turn, helping to overcome road camber effect. |

| Front drive axle square | Square to vehicle centreline ± 2 mm/m | Out-of-parallel produces a turning moment which must be countered by the steer axle. |

| Rear drive axle square | 0 mm/m to 4mm/m left | In some conditions, slight drive thrust to the left induces a turning moment to the right, overcoming road camber. |

| Trailer axles | All square and parallel to pin centreline ± 2 mm/m | Trailer axles perform best when tracking parallel to the centreline of the road. |

Load and Inflation Pressure

It is the air in the tyre that carries the load. Lowering the inflation pressure is equivalent to increasing the load on the tyre.

It should be noted that the maximum cold inflation pressure allowed in Australia is 825kPa (120psi), which has been accounted for.

Recommended Pressure

The correct inflation pressure will depend on: tyre size, service description, actual load, actual speed, fitment (tyres in dual configuration are able to carry less load per tyre because of unequal loading conditions) and operating conditions. Incorrect inflation pressure can result in irregular wear, reduced wear life, damage or even tyre failure.

Inflation pressures should be checked on cold tyres at least every month using a reliable pressure gauge. Always use a sealing type valve cap as the valve core seal is only secondary and must not be relied upon.

Why Rotate

Tyre rotation is a practical means of reducing operating costs by helping to overcome irregular wear patterns and minimising the effects of different wear rates. Rotation can ensure that a tyre’s tread is fully utilised—reducing the cost per kilometre.

Avoid Steer Tyre Vibration

In some cases the driver’s side steer tyre on a prime mover can wear one half of the circumference of the tyre more than the other half (mini-max wear). This creates a light point, which unbalances the tyre and causes a vibration. By rotating steer tyres regularly, this effect is minimised and steer tyre vibration is usually prevented.

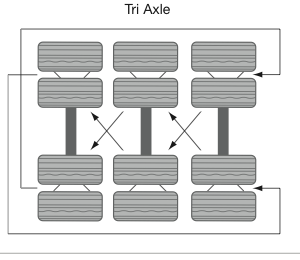

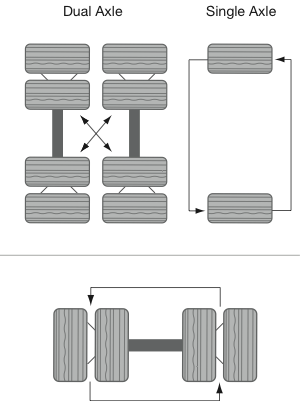

Method

Tyres should be rotated to the positions shown in the diagrams. Note that dual pairs should be rotated in the same pairing, ie. outside tyre remains on the outside, but in the new position.

Typical Frequency:

Steer Tyres: 25,000km

Drive Tyres: 50,000km

Otherwise, rotate as often as required to minimise irregular wear or vibration.

Single axles with dual tyres should be rotated as shown

If the application allows, steer tyres can be rotated onto the drive and trailer axles and drive tyres can be rotated onto the trailer axle.

The table below outlines some common types of irregular wear and some typical causes.

| Appearance | Causes | |

|---|---|---|

Shoulder Edge Wear Even wear in centre but shoulder wearing rapidly. Note: Often results in little or no loss of removal mileage | Incorrect toe; Drive axle misalignment; Worn suspension; Incorrect camber | |

River Wear Circumferential wear along rib edges. Common on free rolling axles. Note: Often a sign of a tyre achieving good mileage | Light loading; Excessive turning; Worn suspension; Assembly lateral runout | |

Heel/Toe Wear Each block worn high to low from front to back. | Mismatched duals; Incorrect inflation pressure; High traction operating conditions; Lack of rotation | |

Feather Wear One side of each rib is worn. Note: Often seen on both steer tyres | Excessive toe; Drive axle misalignment; Bent tie rod or chassis; Worn suspension | |

Diagonal Wear Localised flat spots worn diagonally across the tread. | Mismatched duals; Underinflation; Radial runout; Excessive imbalance; Misalignment; Other wear condition; Loose wheel bearings |

Storage

Tyres being stored should be kept away from direct sunlight, heat sources, ozone creating generators, motors and welders, moisture, dirt, oils and chemicals in order to prevent the tyre from degrading.

Mounting The Tyre-Wheel Assembly

Wheel nuts should be done up in the sequence recommended by the vehicle manufacturer. Furthermore, wheel nuts must be checked within 50km of fitment. Torque levels and sequences are recommended by the vehicle manufacturer. Always use a torque bar to tighten wheel nuts.

Damage

Ignoring tyre damage is dangerous. Damaged tyres must be assessed and where possible repaired by a qualified Bridgestone technician as soon as possible in order to avoid further deterioration of the tyre structure.

Warranty

Any new tyre or tube manufactured by Bridgestone is guaranteed to be free of material and manufacturing defects. Should any such tyre or tube develop a material or manufacturing defect within 5 years of manufacture, Bridgestone will make a pro-rata allowance towards the purchase of a new tube or tyre.

Along with the manufacturer's name and the name of the tyre (e.g. Bridgestone Ecopia), there's always a set of numbers and letters that relate to the size of the tyre.

Here's a rundown on what those numbers mean:

205 is the section width of the tyre in millimetres.

60 is the aspect ratio or tyre profile.

R means it is radial construction.

15 is the diameter of the wheel rim in inches.

We use cookies to ensure you get the best experience. View privacy policy.